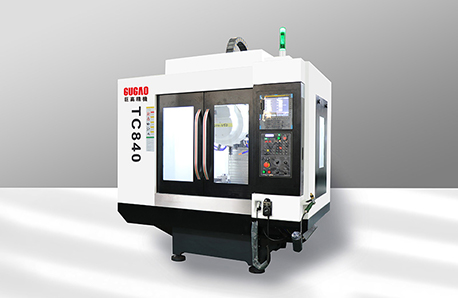

Vertical Machining Center

5 axis cnc machine

Drilling and Tapping Center

Horizontal Machining Center

Gantry Machining Center

Horizontal CNC Lathe

X/Y/Z Travel: 1100/650/600mm

Worktable Size: 1200*600mm

Max.loading Capacity: 800kg

| Item/Content | Parameter |

| Three axis travel | 1100/650/600 (mm) |

| Distance from spindle end face to worktable center | 125-725 (mm) |

| Worktable Size | 1200*600 (mm) |

| Maximum load-bearing capacity | 800 (kg) |

| T-shaped slot | 5*18*110 (mm) |

| Max spindle speed | 12000 (rpm) |

| Spindle diameter Spindle bore taper | ⌀150/BT40 |

| Motor power | 11/18.5(kW) |

| Three axis fast moving speed | 36/36/36 (m/min) |

| Three axis feed speed | 10/10/10 (m/min) |

| Magazine capacity | 24 |

| Max tool diameter/length/weight | ⌀75mm/300mm/7kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 75/150 (mm) |

| Tool exchange time (T-T) | 1.8 (s) |

| Positioning accuracy | 0.010 (mm) |

| repositioning accuracy | 0.006 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Total electrical capacity | 25 (KVA) |

| Tank volume | 420 (L) |

| Machine size | 3000*3100*3000 (mm) |

| estimated weight | 6200 (kg) |

| Main configuration of machine tool | 1 .FANUC 0i MF(5) CNC 2 .Hand held operation unit 3 .Disc-type tool magazine 24T 4 .Automatic lubrication system 5 .Spindle air blowing device 6 .Air curtain protection 7 .Relevant accessories 8 .set of standard technical documents |

| Relevant accessories | 1 .High pressure air gun H-606-1(including tube 8*5-4m, connector) 1 set 2 .CF card(2G),CF card cover,card reader General 1 set 3 .toolbox . Bomei 1 pcs 4 .Phillips screwdriver .6*150 1 pcs 5 .Slotted screwdriver .6*150 1 pcs 6 .Allen wrench 1.5-10MM 1 set 7 .Hanging rings M24 4 pcs 8 .Network communication line .24AWG*4P grey*5000 .1 pcs 9 .External power cable .RVV4*6mm²*5000 1 pcs |

| Brands of the main parts | 1.CNC System FANUC JAPAN 2.Tool Magazine OKADA/DES/POJU TAIWAN 3.Spindle ABIG/Way long/KENTURN China/Taiwan TAIWAN 4.Ball Screw HIWIN/PMI TAIWAN 5.Linear Guide HIWIN/PMI TAIWAN 6.Screw Bearing NSK/NACHI JAPAN 7.Lubricating oil pump.BAOTN/HERG. CHINA 8.Main pneumatic components SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components Schneider/Omron FRANCE/JAPAN Note: The manufacturer reserves the right to replace products with equivalent brands |

| Equipment Customer Installation Preparation Form | 1.Foundation confirmation The machine tool weighs about 6.2T, see the foundation diagram Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil Equipment oil.See "Recommended Oils and Grease Table" for details. 5.Transportation status confirmation 1.Confirm the transportation method according to the factory and surrounding road conditions 2.Meet the net transportation size of the largest component of the machine tool 3.Confirm the lifting method according to the actual height of the factory building 6.Preparation for installing spreader Steel wire rope, safe load-bearing of more than 8T |

| Warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: 1.When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. 2.When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| CNC preferable work condition | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

| Item/Content | Parameter |

| Triaxial travel | 500/400/300 (mm) |

| Distance from spindle end face to center of table | 150-450 (mm) |

| Table area | 650*400 (mm) |

| Maximum bearing capacity | 300 (kg) |

| T-slot (slot number * slot width * spacing) | 3*14*121 (mm) |

| Maximum spindle speed | 20000 (rpm) |

| Spindle diameter/inner taper | ⌀100/BBT30 |

| Spindle motor power | 3.7/5.5(kW) |

| Three axis fast moving speed | 48/48/48 (m/min) |

| Triaxial feed speed (X/Y/Z) | 10/10/10 (m/min) |

| Tool storage capacity | 21 |

| Maximum tool diameter/length/weight | ⌀60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 (mm) |

| Tool exchange time | 1.3 (s) |

| Positioning accuracy (X/Y/Z) | 0.008 (mm) |

| Repeated positioning accuracy (X/Y/Z) | 0.005 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Linear rolling guide Specifications (X/Y/Z) | Ball 30/30/35 (mm) |

| Ball screw Specifications (X/Y/Z) | 32/32/32 (mm) |

| Servo motor specification | 9/9/22.5 (Nm) |

| Total electrical capacity | 15 (KVA) |

| Machine profile dimensions | 1900*2420*2700 (mm) |

| Machine weight | 3050 (kg) |

| Main configuration of machine tool | 1.FANUC 0i MF(5 pack)CNC 1 2.Hand held operation unit 1 3.Clamp-arm tool magazine 21T 4.Automatic lubrication system 1 5.Three-color light 1 6.Air curtain protection 1 7.Spindle air blowing device 1 8.Working light 1 9.Relevant accessories 1 10.Set of standard technical documents 1 |

| Random attachment | 1.Airgun (including tubes and connectors) H-606-1(including pipe 8*5-4m, connector) 1 set 2.CF card(2G),CF card cover, card reader General 1 set 3.toolbox Bomei 1 pcs 4.Phillips screwdriver 6*150 1 pcs 5.Slotted screwdriver 6*150 1 pcs 6.Allen wrench 1.5-10MM 1 set 7.Hanging rings M24 4 pcs 8.Plug M24 2 Pcs 9.External power cable RVV4*6mm²*5000 1 Pcs |

| Machine tool main parts brand | 1.CNC System FANUC JAPAN 2.Tool Magazine POJU TAIWAN 3.Spindle HAOZHI/AIBIG/DEJO China 4.Ball Screw / HIWIN/PMI TAIWAN/TAIWAN 5.Linear Guide / HIWIN/PMI TAIWAN/TAIWAN 6.Screw Bearing NSK/NACHI JAPAN/GERMANY 7.Lubricating oil pump BAOTN CHINA 8.Main pneumatic components SMC/ SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components schneider/omron FRANCE/JAPAN |

| Equipment customer security adjustment preparation table | 1.Foundation confirmation 3T,The machine tool weighs about 3T, see the foundation diagram:Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access 100μm 10mm Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil See Recommended Oils and Grease Table for details. 5.Transportation status confirmation 01.Confirm the transportation method according to the factory and surrounding road conditions 02.Meet the net transportation size of the largest component of the machine tool 03.Confirm the lifting method according to the actual height of the factory building 6. Preparation for installing spreader , 4.5T Steel wire rope, safe load-bearing of more than 4.5T |

| Keep under warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| Working conditions of CNC machine tools | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

X/Y/Z Travel: 1600/700/400mm

Worktable Size: 1700*650mm

Max.loading Capacity: 500kg

| Item/Content | Parameter |

| Triaxial travel | 1600/700/400 (mm) |

| Distance from spindle end face to center of table | 150-550 (mm) |

| Table area | 1700*650 (mm) |

| Maximum bearing capacity | 500 (kg) |

| T-slot (slot number * slot width * spacing) | 5*14*130 (mm) |

| Maximum spindle speed | 20000 (rpm) |

| Spindle diameter/inner taper | ⌀100/BBT30 |

| Spindle motor power | 3.7/5.5(kW) |

| Three axis fast moving speed | 30/36/48 (m/min) |

| Triaxial feed speed (X/Y/Z) | 10/10/10 (m/min) |

| Tool storage capacity | 21 |

| Maximum tool diameter/length/weight | ⌀60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 (mm) |

| Tool exchange time | 1.3 (s) |

| Positioning accuracy (X/Y/Z) | 0.012 (mm) |

| Repeated positioning accuracy (X/Y/Z) | 0.008 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Linear rolling guide Specifications (X/Y/Z) | Ball 35/35/45 (mm) |

| Ball screw Specifications (X/Y/Z) | 40/32/36 (mm) |

| Servo motor specification | 13.7/13.7/22.5 (Nm) |

| Total electrical capacity | 15 (KVA) |

| Machine profile dimensions | 4000*3400*3100 (mm) |

| Machine weight | 6200 (kg) |

| Main configuration of machine tool | 1.FANUC 0i MF(5 pack) CNC 1 2.Hand held operation unit 1 3.Clamp-arm tool magazine 1 21T 4.Automatic lubrication system 1 5.Three-color light 1 6.Air curtain protection 1 7.Spindle air blowing device 1 8.Working light 1 9.Relevant accessories 1 10.Set of standard technical documents 1 |

| Random attachment | 1.Airgun (including tubes and connectors) H-606-1(including pipe 8*5-4m, connector) 1 set 2.CF card(2G),CF card cover, card reader General 1 set 3.toolbox Bomei 1 pcs 4.Phillips screwdriver 6*150 1 pcs 5.Slotted screwdriver 6*150 1 pcs 6.Allen wrench 1.5-10MM 1 set 7.Hanging rings M24 4 pcs 8.Plug M24 2 Pcs 9.External power cable RVV4*6mm²*5000 1 Pcs |

| Machine tool main parts brand | 1.CNC System FANUC JAPAN 2.Tool Magazine POJU TAIWAN 3.Spindle HAOZHI/AIBIG/DEJO China 4.Ball Screw HIWIN/PMI TAIWAN/TAIWAN 5.Linear Guide HIWIN/PMI TAIWAN/TAIWAN 6.Screw Bearing NSK/NACHI JAPAN/GERMANY 7.Lubricating oil pump BAOTN CHINA 8.Main pneumatic components SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components schneider/omron FRANCE/JAPAN |

| Equipment customer security adjustment preparation table | 1.Foundation confirmation 6.2T,The machine tool weighs about 3T, see the foundation diagram:Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access 100μm 10mm Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil See Recommended Oils and Grease Table for details. 5.Transportation status confirmation 01.Confirm the transportation method according to the factory and surrounding road conditions 02.Meet the net transportation size of the largest component of the machine tool 03.Confirm the lifting method according to the actual height of the factory building 6. Preparation for installing spreader , 4.5T Steel wire rope, safe load-bearing of more than 8T |

| Keep under warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| Working conditions of CNC machine tools | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

| Item/Content | Parameter |

| Triaxial travel | 800/400/300 (mm) |

| Distance from spindle end face to center of table | 150-450 (mm) |

| Table area | 900*400 (mm) |

| Maximum bearing capacity | 300 (kg) |

| T-slot (slot number * slot width * spacing) | 3*14*120 (mm) |

| Maximum spindle speed | 20000 (rpm) |

| Spindle diameter/inner taper | ⌀100/BBT30 |

| Spindle motor power | 3.7/5.5(kW) |

| Three axis fast moving speed | 48/48/48 (m/min) |

| Triaxial feed speed (X/Y/Z) | 10/10/10 (m/min) |

| Tool storage capacity | 21 |

| Maximum tool diameter/length/weight | ⌀60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 (mm) |

| Tool exchange time | 1.3 (s) |

| Positioning accuracy (X/Y/Z) | 0.008 (mm) |

| Repeated positioning accuracy (X/Y/Z) | 0.005 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Linear rolling guide Specifications (X/Y/Z) | Ball 30/30/35 (mm) |

| Ball screw Specifications (X/Y/Z) | 32/32/32 (mm) |

| Servo motor specification | 9/9/22.5 (Nm) |

| Total electrical capacity | 15 (KVA) |

| Machine profile dimensions | 2200*2600*2700 (mm) |

| Machine weight | 3300 (kg) |

| Main configuration of machine tool | 1.FANUC 0i MF(5 pack) CNC 1 2.Hand held operation unit 1 3.Clamp-arm tool magazine 1 21T 4.Automatic lubrication system 1 5.Three-color light 1 6.Air curtain protection 1 7.Spindle air blowing device 1 8.Working light 1 9.Relevant accessories 1 10.Set of standard technical documents 1 |

| Random attachment | 1.Airgun (including tubes and connectors) H-606-1(including pipe 8*5-4m, connector) 1 set 2.CF card(2G),CF card cover, card reader General 1 set 3.toolbox Bomei 1 pcs 4.Phillips screwdriver 6*150 1 pcs 5.Slotted screwdriver 6*150 1 pcs 6.Allen wrench 1.5-10MM 1 set 7.Hanging rings M24 4 pcs 8.Plug M24 2 Pcs 9.External power cable RVV4*6mm²*5000 1 Pcs |

| Machine tool main parts brand | 1.CNC System FANUC JAPAN 2.Tool Magazine POJU TAIWAN 3.Spindle HAOZHI/AIBIG/DEJO China 4.Ball Screw HIWIN/PMI TAIWAN/TAIWAN 5.Linear Guide HIWIN/PMI TAIWAN/TAIWAN 6.Screw Bearing NSK/NACHI JAPAN/GERMANY 7.Lubricating oil pump BAOTN CHINA 8.Main pneumatic components SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components schneider/omron FRANCE/JAPAN |

| Equipment customer security adjustment preparation table | 1.Foundation confirmation 3.3T,The machine tool weighs about 3T, see the foundation diagram:Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access 100μm 10mm Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil See Recommended Oils and Grease Table for details. 5.Transportation status confirmation 01.Confirm the transportation method according to the factory and surrounding road conditions 02.Meet the net transportation size of the largest component of the machine tool 03.Confirm the lifting method according to the actual height of the factory building 6. Preparation for installing spreader , 4.5T Steel wire rope, safe load-bearing of more than 4.5T |

| Keep under warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| Working conditions of CNC machine tools | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

X/Y/Z Travel: 1000/650/300mm

Worktable Size: 1100*650mm

Max.loading Capacity: 450kg

| Item/Content | Parameter |

| Triaxial travel | 1000/650/300 (mm) |

| Distance from spindle end face to center of table | 150-450 (mm) |

| Table area | 1100*650 (mm) |

| Maximum bearing capacity | 450 (kg) |

| T-slot (slot number * slot width * spacing) | 3*14*120 (mm) |

| Maximum spindle speed | 20000 (rpm) |

| Spindle diameter/inner taper | ⌀100/BBT30 |

| Spindle motor power | 3.7/5.5(kW) |

| Three axis fast moving speed | 48/48/48 (m/min) |

| Triaxial feed speed (X/Y/Z) | 10/10/10 (m/min) |

| Tool storage capacity | 21 |

| Maximum tool diameter/length/weight | ⌀60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 (mm) |

| Tool exchange time | 1.3 (s) |

| Positioning accuracy (X/Y/Z) | 0.010 (mm) |

| Repeated positioning accuracy (X/Y/Z) | 0.006 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Linear rolling guide Specifications (X/Y/Z) | Ball 30/35/35 (mm) |

| Ball screw Specifications (X/Y/Z) | 40/32/32 (mm) |

| Servo motor specification | 9/13.7/22.5 (Nm) |

| Total electrical capacity | 15 (KVA) |

| Machine profile dimensions | 2700*3220*2900 (mm) |

| Machine weight | 4200 (kg) |

| Main configuration of machine tool | 1.FANUC 0i MF(5 pack) CNC 1 2.Hand held operation unit 1 3.Clamp-arm tool magazine 1 21T 4.Automatic lubrication system 1 5.Three-color light 1 6.Air curtain protection 1 7.Spindle air blowing device 1 8.Working light 1 9.Relevant accessories 1 10.Set of standard technical documents 1 |

| Random attachment | 1.Airgun (including tubes and connectors) H-606-1(including pipe 8*5-4m, connector) 1 set 2.CF card(2G),CF card cover, card reader General 1 set 3.toolbox Bomei 1 pcs 4.Phillips screwdriver 6*150 1 pcs 5.Slotted screwdriver 6*150 1 pcs 6.Allen wrench 1.5-10MM 1 set 7.Hanging rings M24 4 pcs 8.Plug M24 2 Pcs 9.External power cable RVV4*6mm²*5000 1 Pcs |

| Machine tool main parts brand | 1.CNC System FANUC JAPAN 2.Tool Magazine POJU TAIWAN 3.Spindle HAOZHI/AIBIG/DEJO China 4.Ball Screw HIWIN/PMI TAIWAN/TAIWAN 5.Linear Guide HIWIN/PMI TAIWAN/TAIWAN 6.Screw Bearing NSK/NACHI JAPAN/GERMANY 7.Lubricating oil pump BAOTN CHINA 8.Main pneumatic components SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components schneider/omron FRANCE/JAPAN |

| Equipment customer security adjustment preparation table | 1.Foundation confirmation 3.3T,The machine tool weighs about 3T, see the foundation diagram:Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access 100μm 10mm Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil See Recommended Oils and Grease Table for details. 5.Transportation status confirmation 01.Confirm the transportation method according to the factory and surrounding road conditions 02.Meet the net transportation size of the largest component of the machine tool 03.Confirm the lifting method according to the actual height of the factory building 6. Preparation for installing spreader , 4.5T Steel wire rope, safe load-bearing of more than 4.5T |

| Keep under warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| Working conditions of CNC machine tools | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

X/Y/Z Travel: 1300/650/300mm

Worktable Size: 1400*650mm

Max.loading Capacity: 450kg

| Item/Content | Parameter |

| Triaxial travel | 1300/650/300 (mm) |

| Distance from spindle end face to center of table | 150-450 (mm) |

| Table area | 1400*650 (mm) |

| Maximum bearing capacity | 450 (kg) |

| T-slot (slot number * slot width * spacing) | 5*14*120 (mm) |

| Maximum spindle speed | 20000 (rpm) |

| Spindle diameter/inner taper | ⌀100/BBT30 |

| Spindle motor power | 3.7/5.5(kW) |

| Three axis fast moving speed | 30/48/48 (m/min) |

| Triaxial feed speed (X/Y/Z) | 10/10/10 (m/min) |

| Tool storage capacity | 21 |

| Maximum tool diameter/length/weight | ⌀60mm/200mm/3kg |

| Maximum tool diameter (full tool/adjacent empty tool) | 60/80 (mm) |

| Tool exchange time | 1.3 (s) |

| Positioning accuracy (X/Y/Z) | 0.010 (mm) |

| Repeated positioning accuracy (X/Y/Z) | 0.006 (mm) |

| Air source/pressure | 280L/min 6-8bar |

| Linear rolling guide Specifications (X/Y/Z) | Ball 30/35/35 (mm) |

| Ball screw Specifications (X/Y/Z) | 40/32/32 (mm) |

| Servo motor specification | 9/13.7/22.5 (Nm) |

| Total electrical capacity | 15 (KVA) |

| Machine profile dimensions | 3300*3220*2900 (mm) |

| Machine weight | 4400 (kg) |

| Main configuration of machine tool | 1.FANUC 0i MF(5 pack) CNC 1 2.Hand held operation unit 1 3.Clamp-arm tool magazine 1 21T 4.Automatic lubrication system 1 5.Three-color light 1 6.Air curtain protection 1 7.Spindle air blowing device 1 8.Working light 1 9.Relevant accessories 1 10.Set of standard technical documents 1 |

| Random attachment | 1.Airgun (including tubes and connectors) H-606-1(including pipe 8*5-4m, connector) 1 set 2.CF card(2G),CF card cover, card reader General 1 set 3.toolbox Bomei 1 pcs 4.Phillips screwdriver 6*150 1 pcs 5.Slotted screwdriver 6*150 1 pcs 6.Allen wrench 1.5-10MM 1 set 7.Hanging rings M24 4 pcs 8.Plug M24 2 Pcs 9.External power cable RVV4*6mm²*5000 1 Pcs |

| Machine tool main parts brand | 1.CNC System FANUC JAPAN 2.Tool Magazine POJU TAIWAN 3.Spindle HAOZHI/AIBIG/DEJO China 4.Ball Screw HIWIN/PMI TAIWAN/TAIWAN 5.Linear Guide HIWIN/PMI TAIWAN/TAIWAN 6.Screw Bearing NSK/NACHI JAPAN/GERMANY 7.Lubricating oil pump BAOTN CHINA 8.Main pneumatic components SMC/AIRTAC JAPAN/TAIWAN 9.Main electrical components schneider/omron FRANCE/JAPAN |

| Equipment customer security adjustment preparation table | 1.Foundation confirmation 4.4T,The machine tool weighs about 3T, see the foundation diagram:Recommended quick-drying cement for secondary pouring of anchor bolts: high strength non-shrinkage grouting material 2.Preparing the incoming power cable Cable YJV 4*10mm² 3.Preparing for compressed air access 100μm 10mm Air source filtration precision 100μm Air tube outer diameter 10mm 4.Equipment oil See Recommended Oils and Grease Table for details. 5.Transportation status confirmation 01.Confirm the transportation method according to the factory and surrounding road conditions 02.Meet the net transportation size of the largest component of the machine tool 03.Confirm the lifting method according to the actual height of the factory building 6. Preparation for installing spreader , 4.5T Steel wire rope, safe load-bearing of more than 6T |

| Keep under warranty | The warranty period of the machine tool is 12 months from the date of shipment of the equipment. During the warranty period, if machine tool failure occurs due to product quality problems, we will be responsible for free remote technical maintenance support. The following cases are within the warranty period, but are not applicable and the user must pay all repair costs: When the machine tool is damaged due to earthquake, typhoon, flood or other disasters beyond human control. When the product is faulty, rusty or damaged due to improper operation and maintenance by the buyer. After the warranty period, the seller is responsible for ensuring the paid supply of accessories and providing maintenance technical consultation and paid maintenance. The seller charges the cost of replacing faulty parts at a preferential price and provides spare parts for the parts. |

| Working conditions of CNC machine tools | Equipment use environment requirements Maintaining a constant level of ambient temperature is an essential factor for precision machining. 1. The available ambient temperature requires 10℃~40℃. When the ambient temperature is 20℃, the humidity should be 40~75%. In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature requires 15℃~25℃, and the temperature difference shall not exceed ±2℃/24h. 2. Power supply voltage: 3-phase, 380V, voltage fluctuation within ±10%, power supply frequency: 50HZ. 3. If the voltage in the use area is unstable, the machine tool should be equipped with a stabilized power supply to ensure the normal operation of the machine tool. 4. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms. 5. In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the air source requirements, a set of air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake. 6. Keep the equipment away from direct sunlight, vibration sources, heat sources, high-frequency generators, electric welders, etc. to avoid machine production failures or loss of machine accuracy. |

Hi! Welcome back.

How are you doing?

High-end intelligent equipment overall solution provider

+86 138-0962-2930

No. 772, Meijing West Road, Dalang Town, Dongguan, China